Diagram Of Rack And Pinion Steering

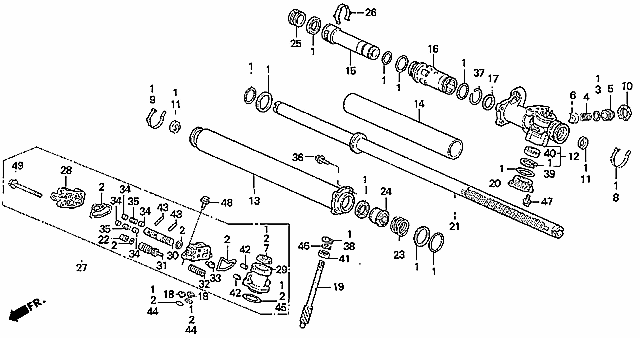

For a typical rack and pinion steering (rps) gear used in light vehicles, the span of movement of the rack is limited to approximately four rotations of the rack of the steering gear is a circular bar with teeth cut across a part of its length.

Diagram of rack and pinion steering. The shaft rotation of the pinion is powered by hand or by a motor to. Note that this diagram does not even include the. It is even showing up on some trucks and suvs. There are fewer moving parts, which makes the steering more responsive.

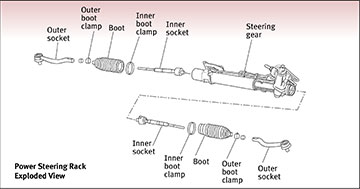

A circular gear called the pinion engages teeth on a linear gear bar called the rack; How does car steering work? The real beauty of a rack and pinion system is that it eliminates much of the steering linkage found in a recirculating ball steering system. Rack and pinion steering is an incredibly popular setup in modern vehicles, but how does it actually work?

Automotive steering system infographic diagram showing both types parallelogram and rack and pinion with all parts for mechanics and road traffic safety science education. Rack & pinion steering has been around for quite awhile and remains the most common type of steering system in todays cars and minivans. How it works, what a steering ratio is, how it is connected to power steering and common problems. You can choose whether the rack axis translates in a positive or negative direction, as the pinion rotates in a positive direction, by using the rack direction.

- Freightliner M2 Chassis Module Wiring Diagram

- 2005 Dodge Caravan Radio Wiring Diagram

- Fuse Box Diagram 2008 Dodge Ram 1500

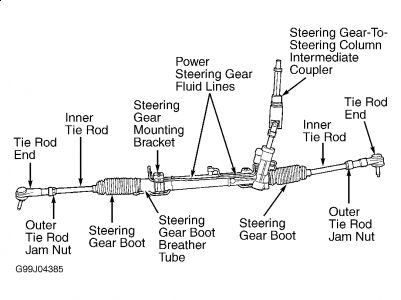

The tie rod at each end of the rack connects to the steering arm on the spindle (see diagram above). Rack and pinions are used for lifting mechanisms (vertical movement), horizontal movement, positioning mechanisms, stoppers and to permit the on the other hand, they are also used in steering systems to change the direction of cars. If you know what causes rack and pinion problems, then. Rotational motion applied to the pinion causes the rack to move.

In a rack and pinion steering system, the steering wheel and steering shaft are connected to a pinion gear. Steering system these days comes with rack and pinion.it works as a central unit receiving input from the driver and sending a mechanical signal… it is not safe to drive with a bad rack and pinion as steering rack failure dangers are grave. The more you turn the steering wheel the more rack is pushed and the sharper the turn will be a little confusing well don't worry you don't have to be a mechanic to steer a vehicle but we wanted you to have visual of exactly that is occurring when you. I designed this model whose specification meets to real steering rack and pinion like rack travel per revolution , overall length of assembly.

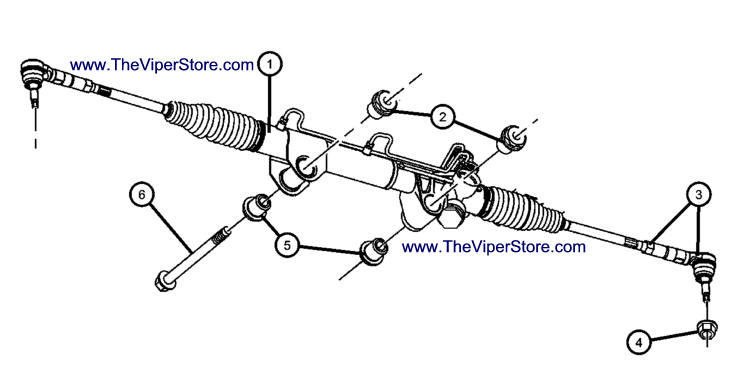

It is actually a pretty simple mechanism. They are composed of a two components. In some vehicles, you must lower the subframe to take the system out, while steering racks on other vehicles are located below the frame. Rack and pinion drives use a rotational motor to affect linear motion via a rack and pinion combination.

The steering system consists of rack and pinion, tie rod end, tire and steering wheel column are modeled in matlab simulink environment based on kinematic model equations is presented. A rack and pinion steering system consists of a pinion (a circular gear) with a rack (a linear gear). Learn how to check a steering rack, or rack and pinion steering system, for wear and damage. The driver commands a turn, turning the steering column which is connected to the pinion input shaft.

The steps followed during the generation of rack are as follows The characteristics of rack and pinion systems in. ← back to model page. Rack and pinion steering gear.

The only difference is the way it is removed from the frame. Ball and socket joint 6. The tie rod at each end of the rack connects to the steering arm on the spindle (see diagram above). The steering gear is bolted to the.

A rack and pinion mechanism can generate a linear motion, which can be adapted into a variety of whimsical craft ideas. Rack and pinion steering system the mostly used steering system is rack and pinion and mostly 80 percent of commercial vehicles are using this type. Ї the pinion moves the rack converting circular motion into linear motion along a different axis ї rack and pinion gives a good feedback there by ●used in older automobiles ●the steering wheel rotates the shaft which turns the worm gear. Part of a steering rack check involves raising the front of the car but retaining its weight on its wheels.

These internal parts are the rack and pinion themselves, and two outer tie rods. A rack and pinion is a type of linear actuator that comprises a pair of gears which convert rotational motion into linear motion. It is actually a pretty simple mechanism. You must also get underneath the car while a helper turns the wheels to and fro.

A rack and pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack), which operate to translate rotational motion into linear motion. This video explains rack and pinion steering, one of multiple types of steering, and how hydraulic power steering works. It's been an incredibly popular engineering choice for years, but have you ever stopped to ponder exactly how it works? Any one can directly use this model in the formula 1 racing steering design.

The resulting undesirable relative movement between wheels and steering gear cause unintended. ●worm gear is fixed to the block and this moves the wheels. Driving the pinion into rotation causes the rack to be driven linearly. The pinion gear acts on the rack gear, then the rack slides sideways inside the gear housing.

The system works by converting a revolving motion into simple linear actuators often consist of some combination of rack and pinion. The chances are your car has rack and pinion steering. Most are pretty durable and last upwards of 100,000 miles. The rack and pinion system is much easier to visualize.

The gearset accomplishes two things.